Introducing Einstein™ Pro XL Dental 3D Printer

Your production-grade 3D printer built for reliability, uptime, and the consistent quality performance you deserve.

Based on 20+ years of R&D from industry leaders in 3D printing technologies, Desktop Health’s Einstein Pro XL dental printer delivers high accuracy and high throughput, consistently, to keep your large-scale production on schedule.

Predictable 3D Printing

- Precision fit and finish with 45 µ in XY

- Dual-linear slides for superior stability in Z

- Consistent, reliable uptime at an affordable price

Einstein Pro XL. Made to fit your throughput needs

Improve overall efficiency and turnaround time with Einstein Pro XL's reliability and low-cost per print, high-accuracy models, night guards, restorations, dentures, custom trays, and more.

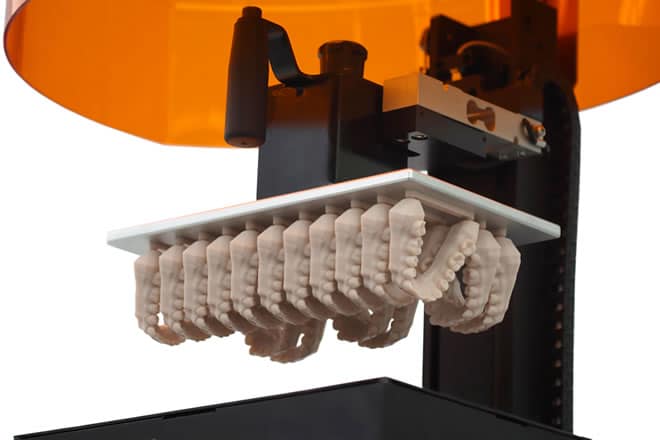

Dental and Orthodontic Models

- 30 full arches in 68 minutes

Night Guards and Bite Splints

- 52 guards in 186 minutes

Denture Bases and Partials

- 18 denture bases in 130 minutes

Monolithic and Try-in Dentures

- 14 dentures in 79 minutes

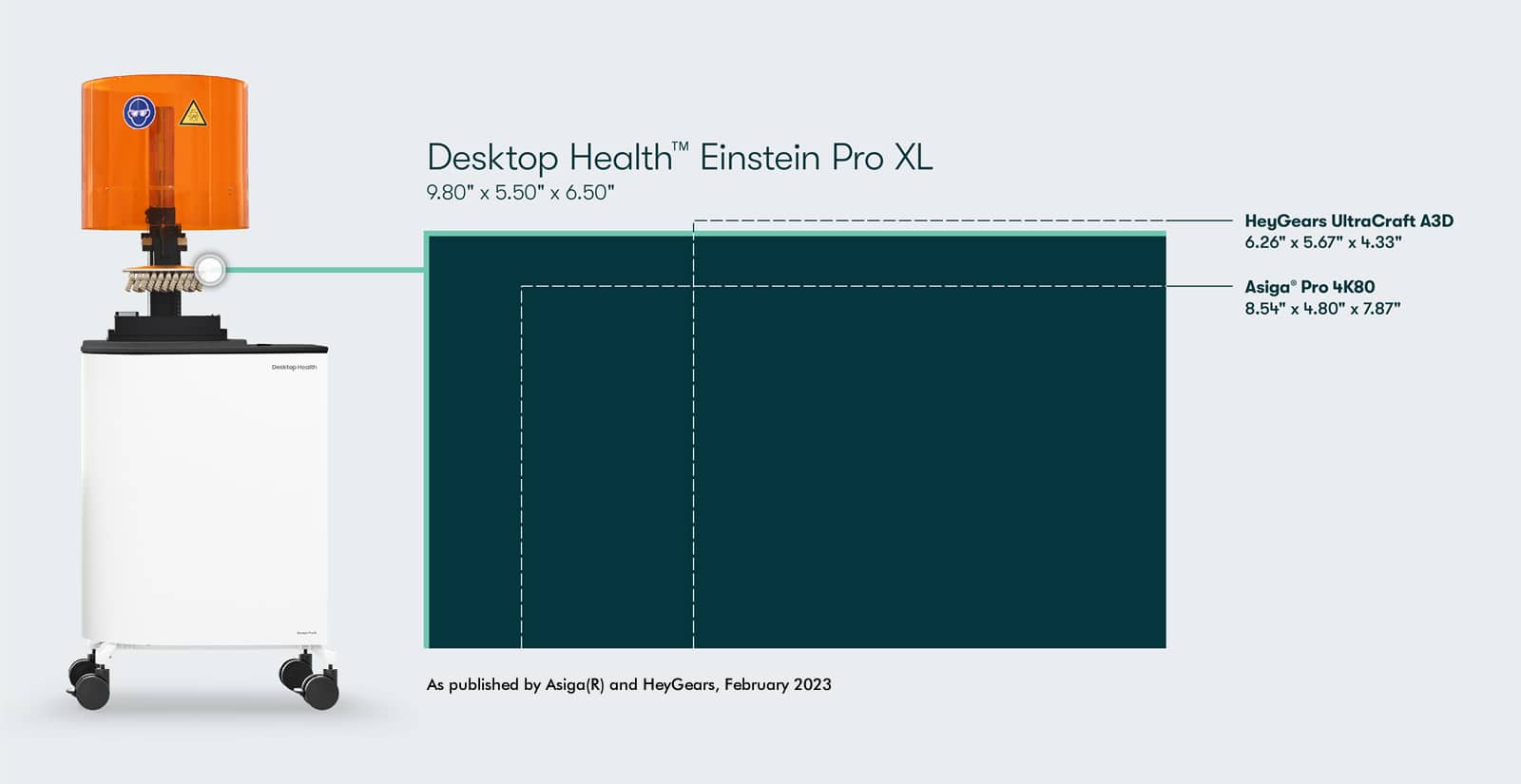

Largest build plate in its category

There are many dental 3D printing options available in the market today. Einstein Pro XL delivers the total lab and orthodontic value featuring the largest build plate in its category versus leading competition for more prints in fewer jobs.

Einstein Pro XL is capable of printing a wide range of dental resins for 3D printed models, night guards, and more. However, it’s the only high-volume printer qualified to print Flexcera™ Smile Ultra+, an FDA 510(k) cleared Class II material for strong, beautiful, and permanent and temporary dental restorations, including veneers, inlays/onlays, crowns, bridges, and dentures.

Forget the contracted multi-year lease. High accuracy and reliable throughput are yours today at a show special price at LMT Lab Day and Chicago Midwinter in Chicago, IL.

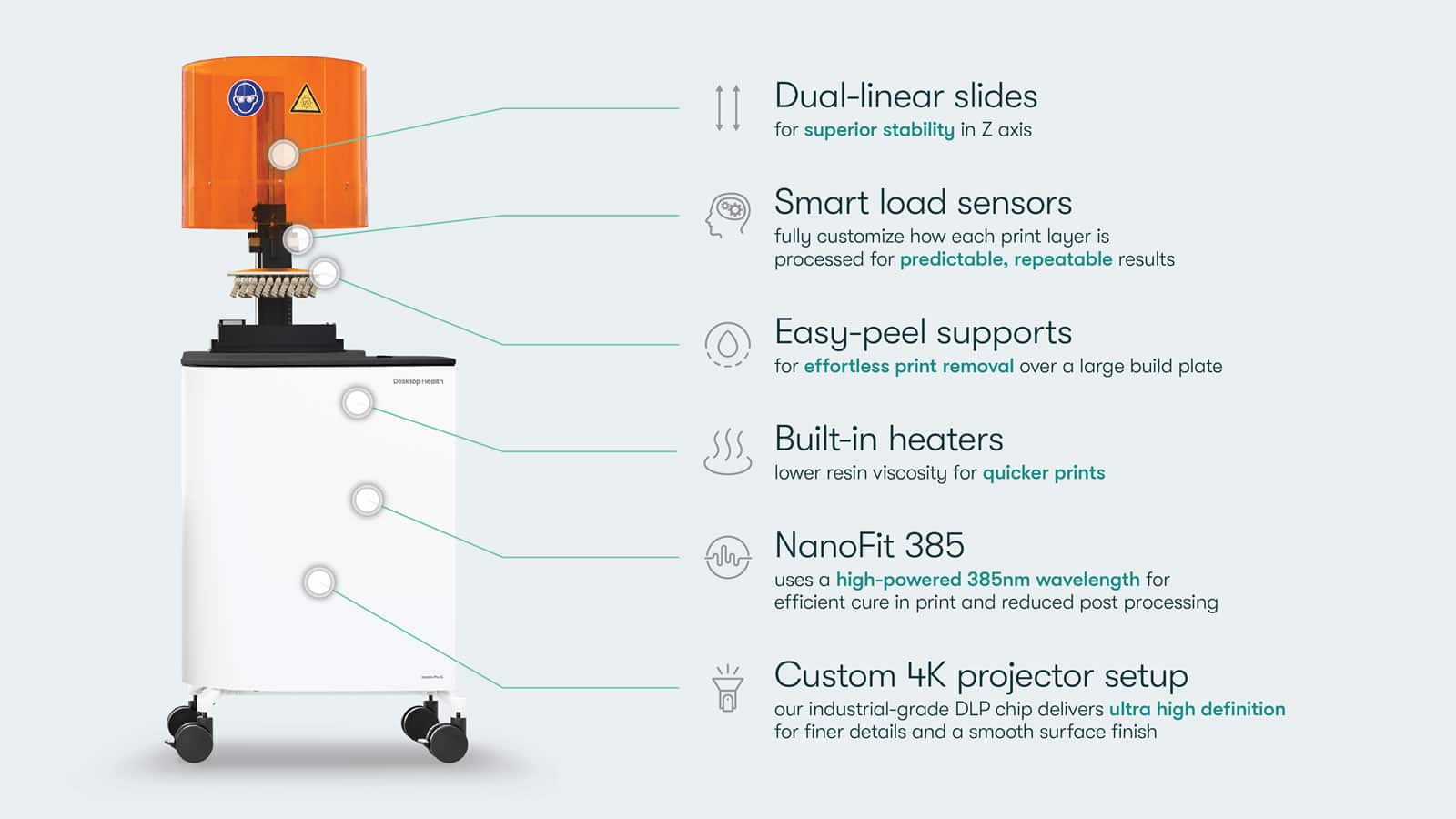

The Secret to Einstein’s 3D Printing Performance

Built for Reliable 3D Printing

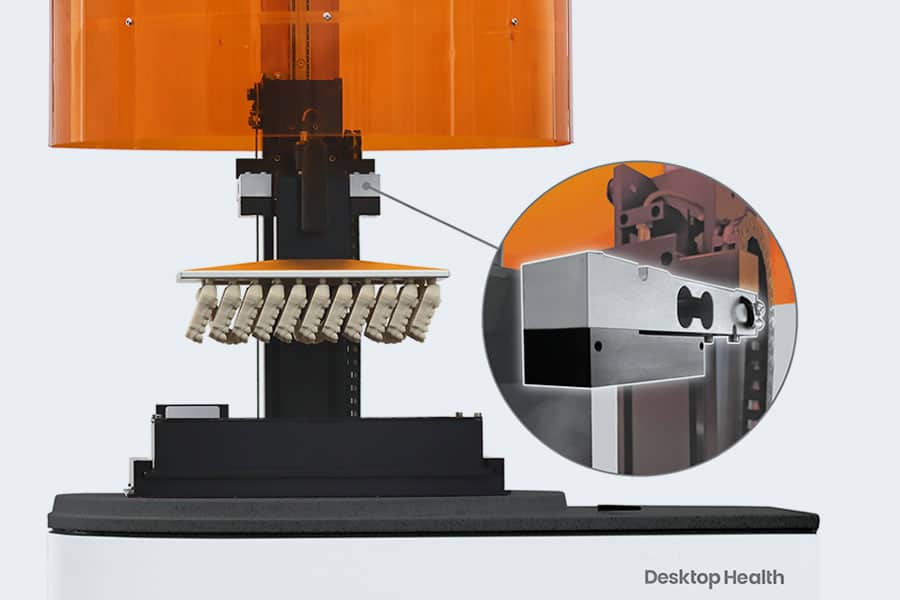

REPEATABILITY & SPEED WITH HYPERPRINT™

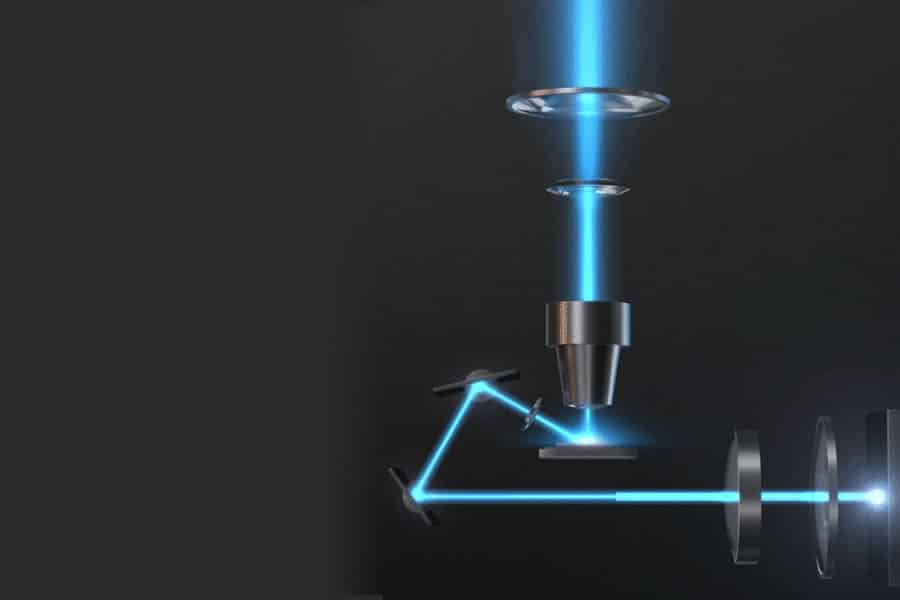

An efficient combination of heat and closed-loop feedback, driven by intelligent load sensors (pictured right), fully customizes how each print layer is processed for repeatability, quality assurance and speed.

Built-in heating, Einstein thins the viscosity of polymer resins for faster prints. No separate heating unit required.

- Exceptionally reliable printing

- Extends resin tray life

HIGH RESOLUTION PRINTING WITH CUSTOM DESIGNED OPTICS

Harnessing the power of an industrial grade DLP® chip allows for higher contrast that results in finer detail parts.

Our optics are designed from the ground up to reduce image distortion and ensure the maximum amount of energy is transferred from the LED light source for:

- Exceptionally precise curing

- Resulting in finer detail parts

HIGH RESOLUTION 3D PRINTING WITH INDUSTRIAL GRADE DLP® CHIP

DLP chips come in a variety of configurations, from industrial chips designed for 3D printing to less expensive chips intended for video projectors found in many competitors.

While some print technologies choose to use these inexpensive chips to reduce costs, Desktop Health uses true industrial chips, which allows for:

- Higher contrast ratios

- Resulting in finer detail parts

SOFT SMOOTH EDGES WITH PIXEL TUNING SOFTWARE

Desktop Health 3D printers use advanced DLP® chips that can deliver pixels with more sophistication.

Tightly controlling the intensity of the light energy to each individual pixel, projectors can create soft and smooth edges, eliminating the stair-stepping effect.

- Improved surface finish

- Resulting in finer detail parts

Note: illustration is show from a top-down view (XY plane)

-

Fig. A: Pixel tuning (varying power intensity) is applied along the edge of a part

-

Fig B: The resulting part growth from the inside of the part out

-

Fig C: The final resulting cross section after polymerization is complete

Customer experience: hear from the expert

"I have been printing in-office since 2014 and ever since we started printing with the Einstein Pro XL 3D printer, we have been able to double our production in fewer prints while satisfying our standard of high-accuracy models. We are very excited about the high throughput and reliable precision of this new printer from Desktop Health."