Desktop Health™ delivers 3D printing technology

trusted for 20+ years to improve patient lives.

Our high-accuracy 3D printers, paired with premium biocompatible materials, have been proven to deliver reliable, regulatory-approved dental and medical solutions.

Backed by Decades of Research in Dental & Bio 3D Printing

20+

Years of R & D

950+

Total Pending or

Registered Patents**

1400+

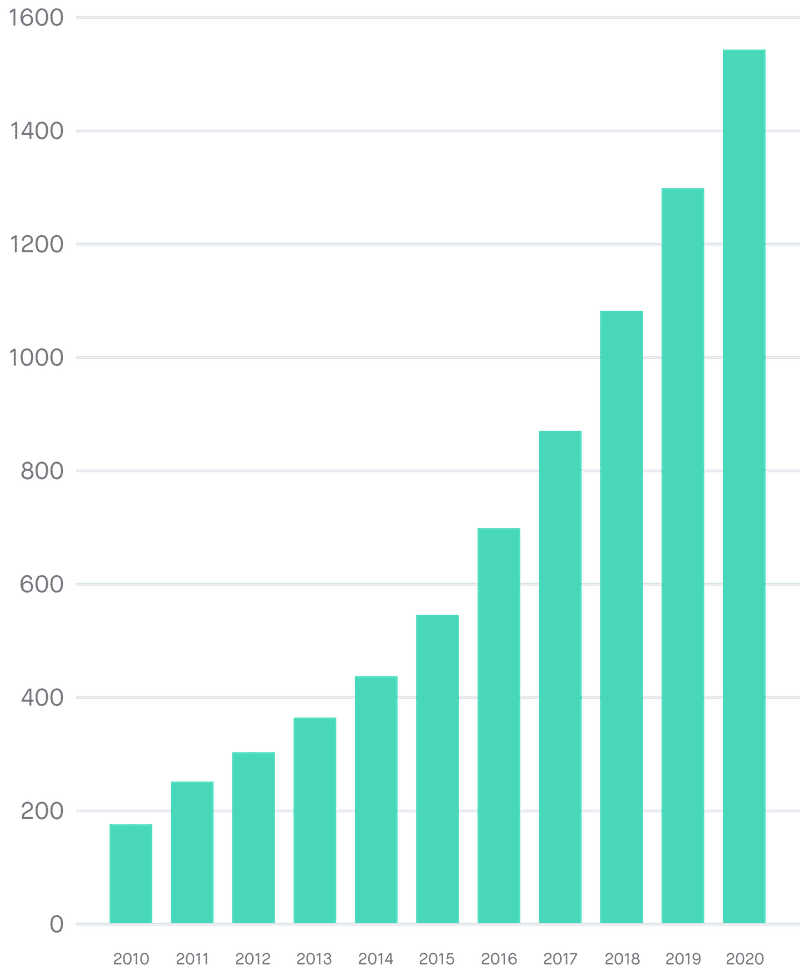

Published Papers*

*publications referencing Bioplotter based on Google Scholar citations 2010 through 2023 [1]

***including various 3D printing technology and applications as well as biofabrication [2]

More research publications citing our Bioplotter®

than comparable bio-printers

- Flexible choice of materials with applications in bone regeneration, cartilage regeneration, soft tissue fabrication, drug release, and organ 3D printing.

- Use cases across education, R&D, and manufacturing

- Trusted by the leading institutions and companies in tissue engineering

- Over half a dozen print modalities supported

*publications referencing Bioplotter based on Google Scholar citations 2010 through 2020 [1]

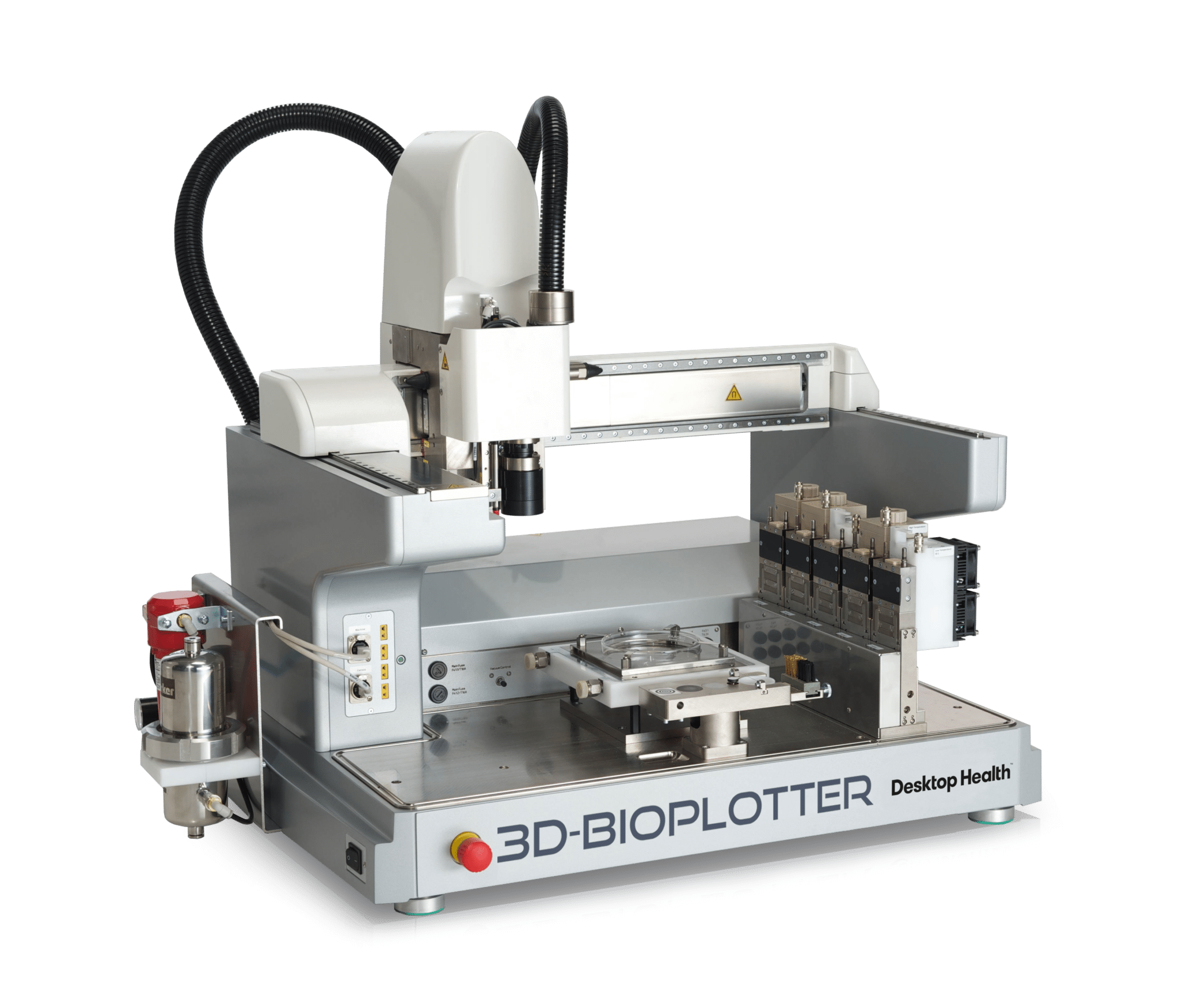

Industrial-grade 3D Printing, Optimized for Healthcare

Born from EnvisionTEC, founded in 2002 by leading experts in advanced manufacturing, material science, and engineering with the goal of making quality dental and medical 3D printing for personalized, patient care.

Einstein for Dental 3D Printing speed

and biocompatible materials

3D-Bioplotter for Medial-grade 3D Bioprinting manufacturing, research, and development

Personalized Patient Care powered by Industry Leaders

Since being acquired by Desktop Metal in 2021, we have evolved into the Desktop Health brand to leverage industry-leading engineering and scientist to further advance healthcare with ground-breaking applications in dental, medical, and more.

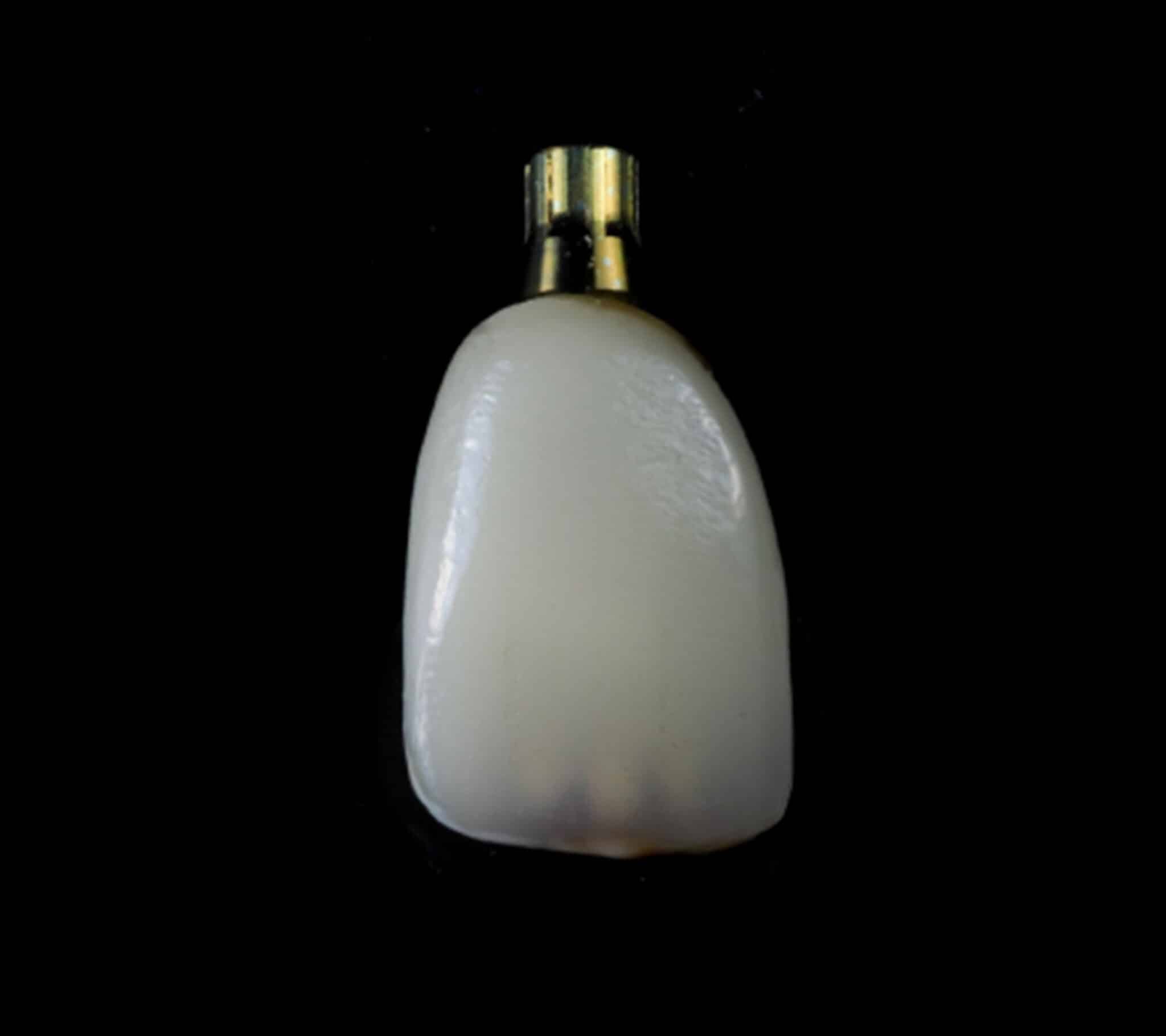

Photopolymers

Materials and processes designed for hearing aid and custom dental applications used for immediate medical device fabrication.

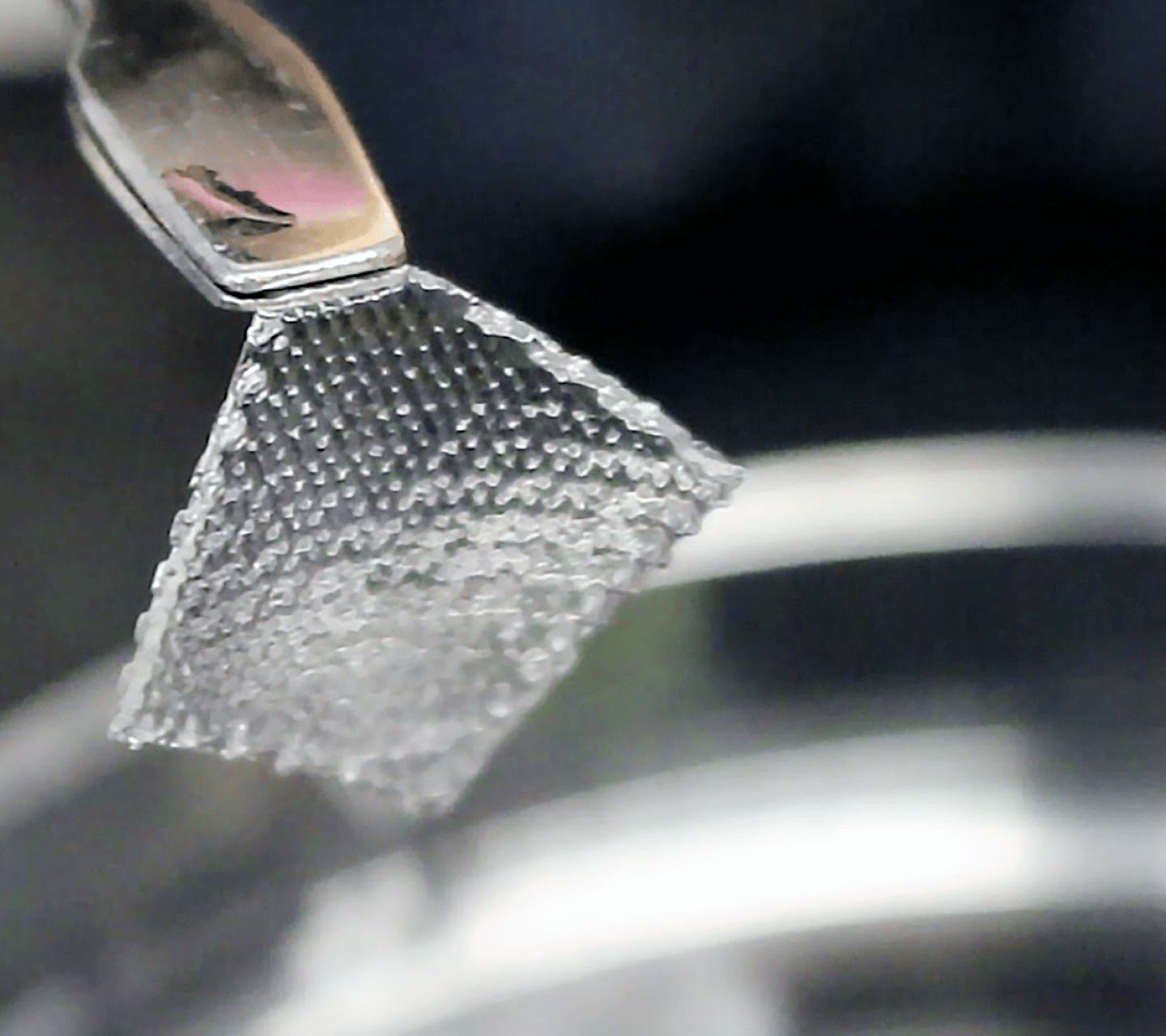

Ceramics

Bio-active, osteoinductive and osteoconductive materials that are designed to promote bone growth in the implantation area. Used in critical size defects as bone grafts with complex inner patterns that mimic the surrounding bone's mechanical properties, and as custom ceramic implants in maxillofacial applications.

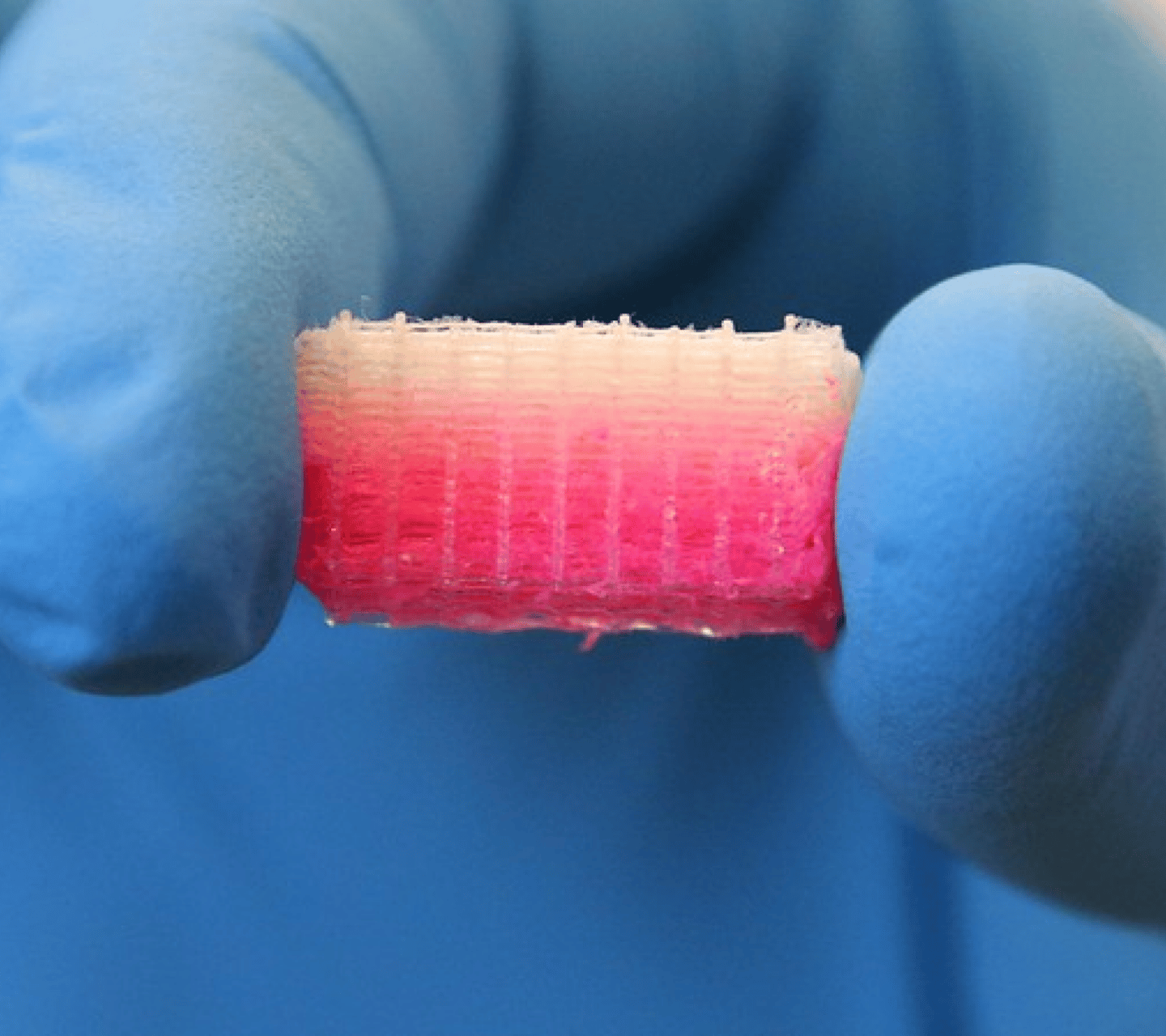

Hydrogels & Cells

Materials designed to be both biocompatible and cell-friendly, capable of supporting a variety of applications in bone regeneration, cartilage regeneration, soft tissue fabrication, drug release, and organ 3D printing.

Thermoplastics

Synthetic polymers designed to be biocompatible and biodegradable. The flexibility of thermoplastics allows for cartilage regeneration applications, such as knee meniscus or trachea defects.