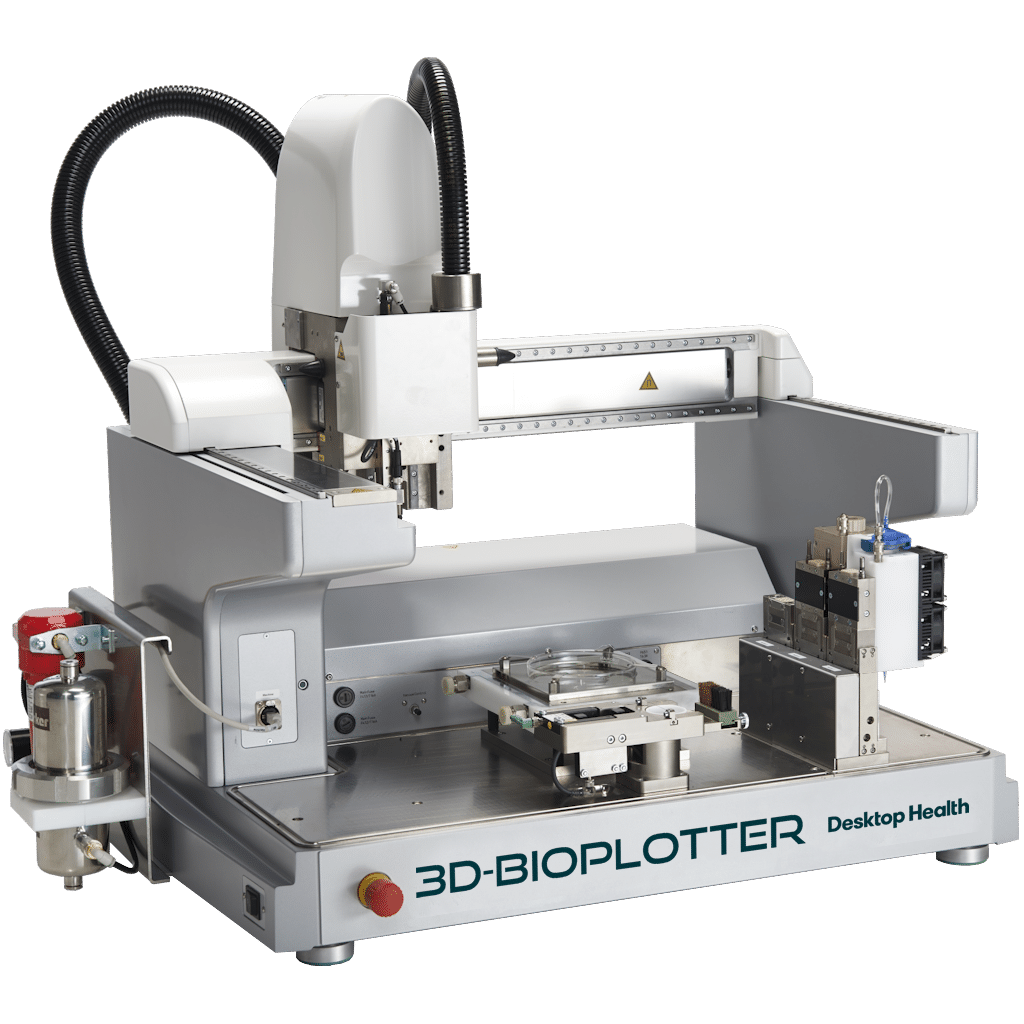

3D-Bioplotter® Developer Series

The 3D-Bioplotter Developer Series is designed for research groups new to the field of tissue engineering, as well as for specialized use, where limited capability may still meet requirements. It consists of the same basic hardware and software as the Manufacturer Series but with reduced park position functionality. It is still capable of using multiple modular head types and an optional heated platform.

Machine Properties

Filters Included

Particle and Sterile

Platform Temperature Control

Yes (Chiller not included): -10° - 80°C (14° - 176°F)

Max Heads

3

Head Temperature Range

Low: 0° – 70°C (32° – 158°F) or High: 30° – 250°C (86° – 482°F)

No. of Heads Included

2

Tool Changer Type

Modular Tool Changer

Cartridge Sizes

10 - 30 ml (.3 - 1.0 fl oz)

Other Usable Modules

All

Platform Height Control

Automatic

Needle Calibration

Photo Sensor

Material Calibration

Manual

External Temp. Ports

0

Included PC

Professional PC

Build Volume (XYZ)

150 x 150 x 150 mm (5.91 x 5.91 x 5.51 in.)

Speed

0.1 - 150 mm/s (0.004 - 5.91 in/s)

Minimum Strand Diameter

0.100 mm (0.004 in.) Material Dependent

Axis Resolution (XYZ)

0.001 mm (0.00004 in.)

System Properties

- A new user management allows users to both share projects, materials and patterns, as well as have their own separate set of files for improved overview and security.

- Input of outer shapes through STL files.

- Multi-part and multi-material capable through the use of an automatic tool changer and multiple print heads.

- Database of volume support structures for complex shapes.

- Database of inner patterns (user-editable) in the controlling software, avoiding requiring patterns in the STL files.

- Complex inner pattern with straight lines, zig-zag shapes and wave forms as well as hexagon shapes, including shift functions for “in between the lines” printing

- Database of materials (user-editable) with all process parameters.

- Material life time control to avoid scaffold fabrication with degraded materials.

- Individual temperature control of each printing head, both in the parking positions, as well as during printing

- Temperature curves with up to 5 set points and waiting times.

- Complete control of all printing parameters (temperature, pressure, speed, etc) through the software.

- Automatic platform height control for petri dishes, well plates, as well as other printing surfaces.

- Improved surface finish of fabricated parts using randomized start position in outer contours.

- 2D Dot-Printing (Biopatterning) capability

- Low-Temperature Print Head: 0° – 70°C (32° – 158°F) with disposable PE cartridges.

- High-Temperature Print Head: 30° – 250°C (86° – 482°F) with reusable stainless steel cartridges.

- UV Curing Head (365 nm).

- Needle cleaning station, with automatic cleaning before and during the print project available.

- Luer Lock needle tips, 0.1mm to 1.0mm inner diameter available.

- Automatic recalibration of park position coordinates in extensively used 3D-Bioplotters (Manufacturer & Developer Series only).

- LOG file creation after project completion with all relevant data.

- Footprint (L x W x H): 976 x 623 x 773 mm (38.4 x 24.5 x 30.4 in.)

- Weight: About 110 kg (243 lbs)