Dipl. Chem. Carlos Carvalho

Process & Material Development

The Portuguese Chemist Behind ETEC’s 3D-Bioplotter®

It’s safe to say that nobody knows more about the

ETEC 3D-Bioplotter® than Carlos Carvalho.

In 1996, Carlos left Portugal for Germany to study chemistry, graduating in photopolymerization, at the Philipps-Universität Marburg. After graduating in 2003, he went on to begin his Ph.D. program at the Albert Ludwig University of Freiburg, where a bioprinter was already under development.

“At the time, the machine was very new,” Carlos recalled. “No real applications had been done yet.”

The main topic of his study there became developing medical applications for this newly developed bioprinter, which would eventually become known as the EnvisionTEC 3D-Bioplotter.

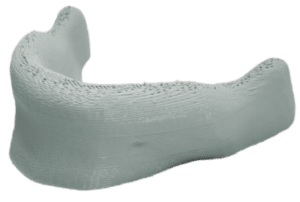

A jaw implant 3D printed on EnvisionTEC's 3D-Bioplotter system.

During that time, Carlos worked on his Ph.D. thesis using the first, second and third generations of the 3D-Bioplotter, manufacturing implants in the young field of biofabrication with established biocompatible or biological materials.. He also co-authored

11 technical papers with different cooperative research groups.

Popularity of the 3D-Bioplotter soared among researchers worldwide as new materials, patterns and strategies for working on the printer were developed.

Carlos joined ETEC in 2009, where he started development on the 4th generation 3D-Bioplotter, which was specially designed to meet specifications for use in a clean room and in clinical trials.

Being an expert in the field of 3D bioprinting today, Carlos said several aspects of the EnvisionTEC 3D-Bioplotter stand out in the biofabrication market.

“It’s a popular tool because it’s a very flexible, but also user-friendly machine,” Carlos explained. “Our aim is to provide researchers and industry with the best instrument and software possible, so that they can concentrate on advancing regenerative medicine and not waste their time on machine development.”

Depending on which model being used —

Starter,

Developer or

Manufacturer — modular components allow for the use of a wide variety of materials in easy to change cartridges. Standard Luer-Lok syringes and needle tips are used, and a software package is included that gives the user enormous control for developing inner structures and allows the use of multiple materials in one single part with an automatic tool changing system.

Additionally, the EnvisionTEC 3D-Bioplotter is the oldest brand bioprinter in the market backed by the most published research. Carlos keeps up with all the research now being done on the 3D-Bioplotter around the world and he built a

publicly available database to keep track of technical papers citing the 3D-Bioplotter. .

“I personally find it fascinating seeing what researchers will do with it next,” he said, citing as an example a 2012 paper about 3D printing graphene that was done with the 3D-Bioplotter.

“Nobody had thought about adding electroconductive materials, and it created a whole new area of research,” Carlos said. “That idea then developed to biosensors and muscle regeneration, which require electrical impulses to expand and contract.”

All of the foundational research done on the 3D-Bioplotter also allows researchers to build upon each other’s work, so they don’t have to retread over prior research, and they can speed time to discovery and eventual human trials of medical parts.

“We do see this is the final aim of our customers,” Carlos said, “to eventually use the EnvisionTEC 3D-Bioplotter in hospitals for real-life applications. Bone regeneration results published in a 2016 study on primates are a good example of this.”

Today, there are many new bioprinters entering the market, but Carlos said they “are extremely simplified versions of what we do,” and these machines often lack the accuracy, resolution and repeatability necessary for serious research and clinical trials.

Said Carlos: “We are the leading company in this field. The word 'bioplotter' can even be found in numerous peer-reviewed papers as a synonym for 3D-bioprinters worldwide.”