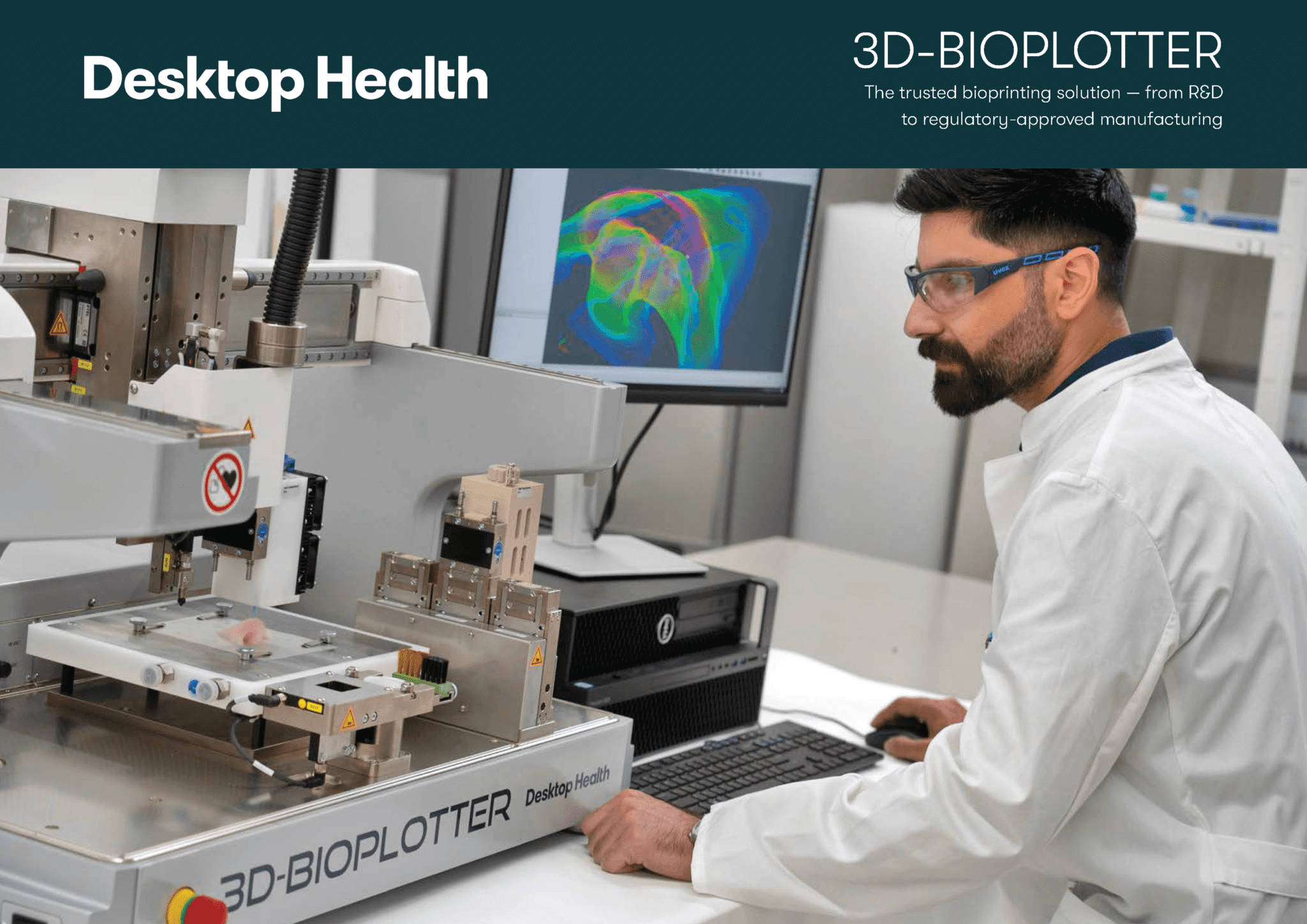

3D-Bioplotter® For Bioprinting

There’s Only One 3D-Bioplotter®

Well, actually, we have three. But when medical researchers and manufacturers are talking about “the bioplotter,” that’s a nod to our bioprinter technology. A recognized world leader in biofabrication, Desktop Health’s 3D-Bioplotter family is being used for groundbreaking medical research and manufacturing. Introduced in 2000, the 3D-Bioplotter is the most seasoned bioprinter in the market, backed by the most research, more than 700 research papers to date.

“I personally find it fascinating seeing what researchers will do with it next,” said Carlos Carvalho, who led the development of the fourth generation of the 3D-Bioplotter and has worked on the bioprinter since its infancy at the University of Freiburg in Germany. Carvalho cited as an example a 2012 paper about 3D printing graphene that was done with the 3D-Bioplotter as launching an entirely new area of research. The EnvisionTEC bioprinter has also been used to fabricate hyperelastic bone, ovary implants, a placenta model and is being used in bone regeneration research.

With robust levels of functionality, the Developer and Manufacturer series processes open-source biomaterials using air or mechanical pressure to a syringe, which can fabricate scaffolds to create tissue, organs and more. Our bioprinters are extremely accurate with X-Y repeatability down to 1 μm. All models have been designed for use in a sterile biosafety cabinet, meet standards for clinical trials and offer build sizes up to 192.4 cubic inches.

Developed at the University of Freiburg, the bioprinting technology used by the 3D-Bioplotter allows for maximum flexibility for research and development. The system uses modular components, such as sterilized heating and cooling cartridges, standard Luer-Lok syringes with standard needle-tip sizes and an easy-to-use 365 nm UV curing head. “It’s a popular tool because it’s a very flexible, but also user-friendly machine,” Carlos explained. The software also allows for maximum freedom in combining different materials using different temperatures.

Many machine features vary between models. For example, the Manufacturer model allows for 5 print heads and also includes a heated platform and sterile filter, which is recommended for cell and organ printing.

The 3D-Bioplotter family is also made with high-quality components and is extremely reliable, allowing R&D to spend more time printing.

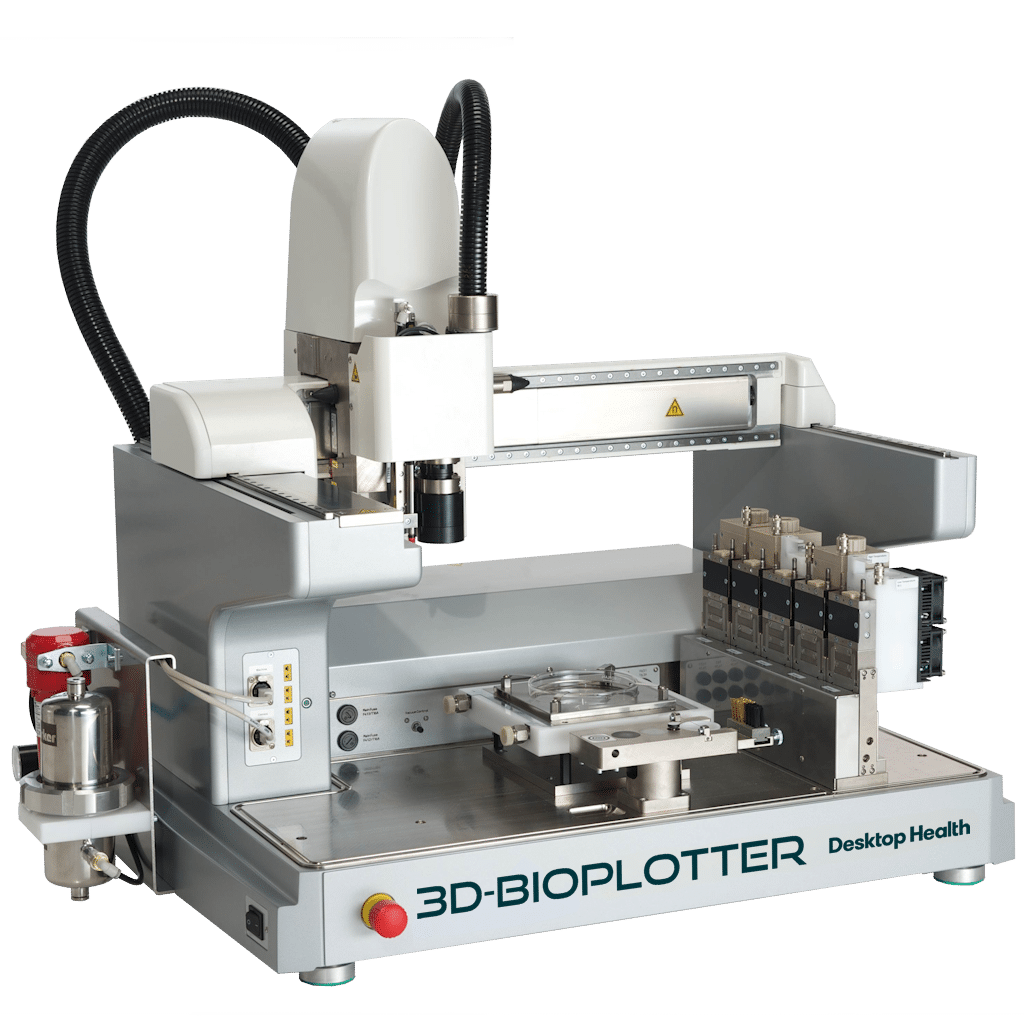

3D-Bioplotter® Manufacturer Series

The 3D-Bioplotter Manufacturer Series was designed as a tool for advanced tissue engineering and also for use in a production environment. It is the most versatile and advanced of the 3D-Bioplotter options and is capable of utilizing up to 5 materials in a build as well as UV curing capabilities and both heated and cooled platform options.

Filters Included

Sterile and Particle

Platform Temperature Control

Yes (Chiller Included): -10° - 80°C (15° - 176° F)

Primary Markets

Biofabrication

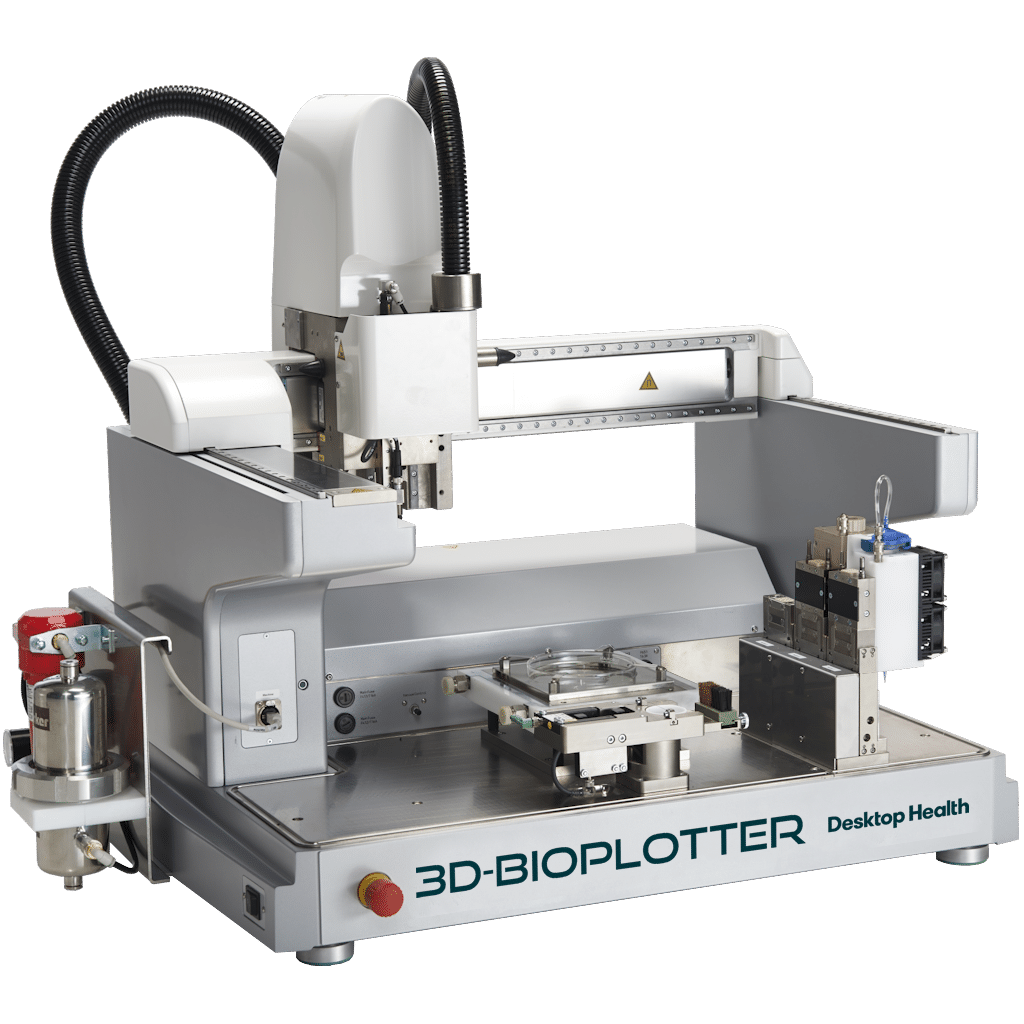

3D-Bioplotter® Developer Series

The 3D-Bioplotter® Developer Series is designed for research groups new to the field of tissue engineering, as well as for specialized use, where limited capability may still meet requirements. It consists of the same basic hardware and software as the Manufacturer Series but with reduced park position functionality. It is still capable of using multiple modular head types and an optional heated platform.

Filters Included

Particle and Sterile

Platform Temperature Control

Yes (Chiller not included): -10° - 80°C (14° - 176°F)

Primary Markets

Biofabrication